DIGITAL TRANSFORMATION

Accelerate and scale digital initiatives with a data backbone that represents the configuration of your plant

Leap past the roadmaps and pilots to scaling digital across your organization. Use the power of your existing data sources, with no field personnel time required to implement a data foundation that represents your plant.

Offer your internal and external data consumers the industrial version of Google Maps and feed your AI models with the context of your plant.

Data powers digital

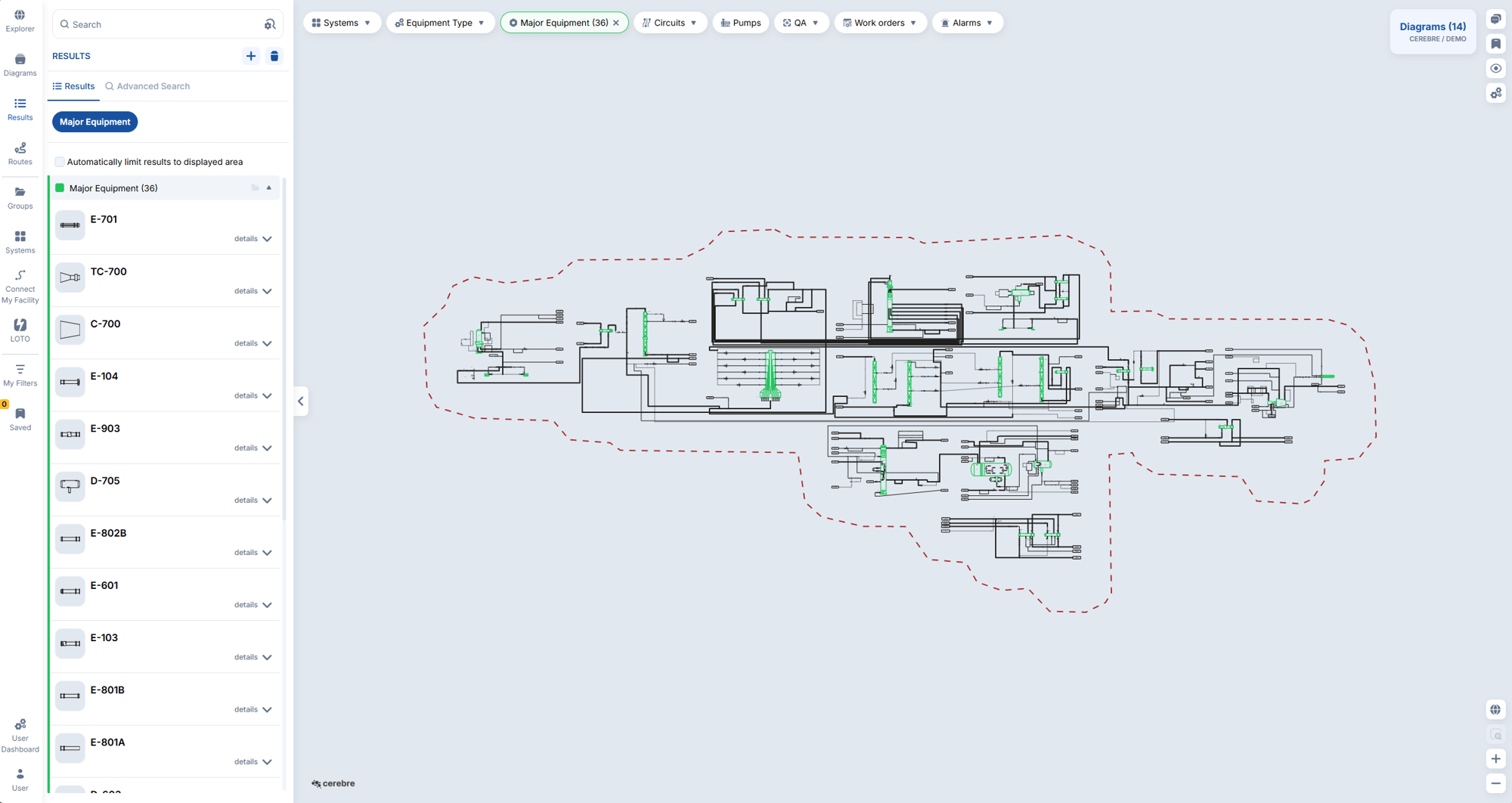

cerebre builds a map of your plant to power your visualizations, analytics, and day-to-day search of your data.

This data and navigation bridges the gap between the field and corporate and enables you to tackle the challenges of brownfield digitization with no operator time required.

Leverage the power of the modular and agonistic capability to avoid proprietary vendor lock-in and to invest in the data you own and control.

Enrich Digital Twin initiatives and unlock knowledge capture at scale

Power your digital twin representations with the context of your equipment relationships. Enable your Operators to alternate between visualizations of their plant with an underlying data model that contains physical plant relationships.

- Dynamically visualize any area of the plant’s equipment relationships to solve a problem.

- Bridge the gap between the field operator, engineer, and specialist to drive collaborative and informed decision-making

- Consolidate documents and data and enable instant access to critical information plants need to drive differentiated work processes.

Connect your OT, IT, and modeling domains with a unified model plant model

Your OT teams leverage manually created distinct views and disconnected data to run their plants. Your IT teams are faced with limited hierarchy control and a collection of bespoke tooling and a broad range of stakeholder demands. Create a unified lens with dynamic navigation to enable stakeholders across all functional areas to consume and enrich the same plant model. Translate user activity and actions into insights that can power your AI models.

- Dynamically visualize any area of the facility required to solve your problem. Bridge the gap between field operator, engineer, and specialist to drive collaborative and informed decision-making.

- Integrate to your digital twin platforms or your internal data management platforms to enable your internal and external data consumers to get value out of your data.

- Consolidate documents and data and enable instant access to critical information plants need to drive differentiated work processes.

Enable enterprise analytics and unlock insights across multiple engineering domains

Classify and structure data into consistent naming conventions and operating systems.

- Conduct comparative analysis across any equipment type, system, unit, and facility.

- Heat map trends across dynamic asset configurations and data. View easy to read results in context to the P&ID.

- Restructure facility data based on the problem you are solving for. Rely on infinite flexibility and dynamic relationship modeling to feed any use case.

Related resources

No context, no intelligence –

The case for a plant data model

Why AI fails without structure and how a data model gives your plant the context it needs.

Digitizing the plant –

The cerebre presentation

See how cerebre helps you transform plant schematics into searchable, smart assets.

We enable your AI –

An overview document

Learn how PlantGraph powers AI with data that’s contextual, connected, and usable.

Explore solutions for Digital and Data teams

Control system and process historian integrated modeling

Combine plant operating conditions with control loop context to quickly mitigate plant upsets, quality deviations, and equipment malfunctions. Save time, reduce errors, and coordinate responses more effectively.

Visualize 2D and 3D environments to optimize data collection and task execution

Integrate high fidelity plant data with real world 3D laser scanning or modeling environments to power mobile field data collection and task execution.

Scale your offshore teams with plant context

Provide your remote teams with a risk-free training ground and digital tooling to collaborate with experts in the plant. Power these teams with the ability to search, integrate, and analyze any aspect of your plant. Standardize procedures and workflows enterprise-wide.