Maximize uptime, reduce risk at Amgen

Get context related insights for Amgen's facilities powered by cerebre's leading industrial knowledge graphs.

x

What we heard from you

From our recent conversations, we understand that:

- Unplanned downtime due to equipment failure, human intervention, and inefficient changeovers is a major concern.

- Critical equipment (e.g., freeze dryers, vacuum pumps) can cause batch loss or quality deviations if not perfectly reliable.

- Data is fragmented across Maximo (CMMS), P-Historian, IoT devices, process control systems, and document management tools.

- Investigating non-conformance events (NCs) and preventative maintenance planning is difficult due to a lack of integrated context.

- There is a significant opportunity to optimize reliability and scale visibility into asset health and process interdependencies.

Amgen current challenges

Amgen is facing systemic barriers to operational reliability:

- High-value products at risk from fragile, aging, or hard to monitor equipment.

- Human interventions in sterile filling and packaging lines introduce variability.

- Systemic issues like glass breakage, line stoppages, or sensor alarms aren't easily traced to root causes.

- Knowledge is siloed between Engineering, Ops, and Quality, slowing down resolution.

- Your current CMMS (Maximo), and IoT systems aren’t contextually connected, making downtime mitigation and planning reactive.

![]() What cerebre brings to the table

What cerebre brings to the table

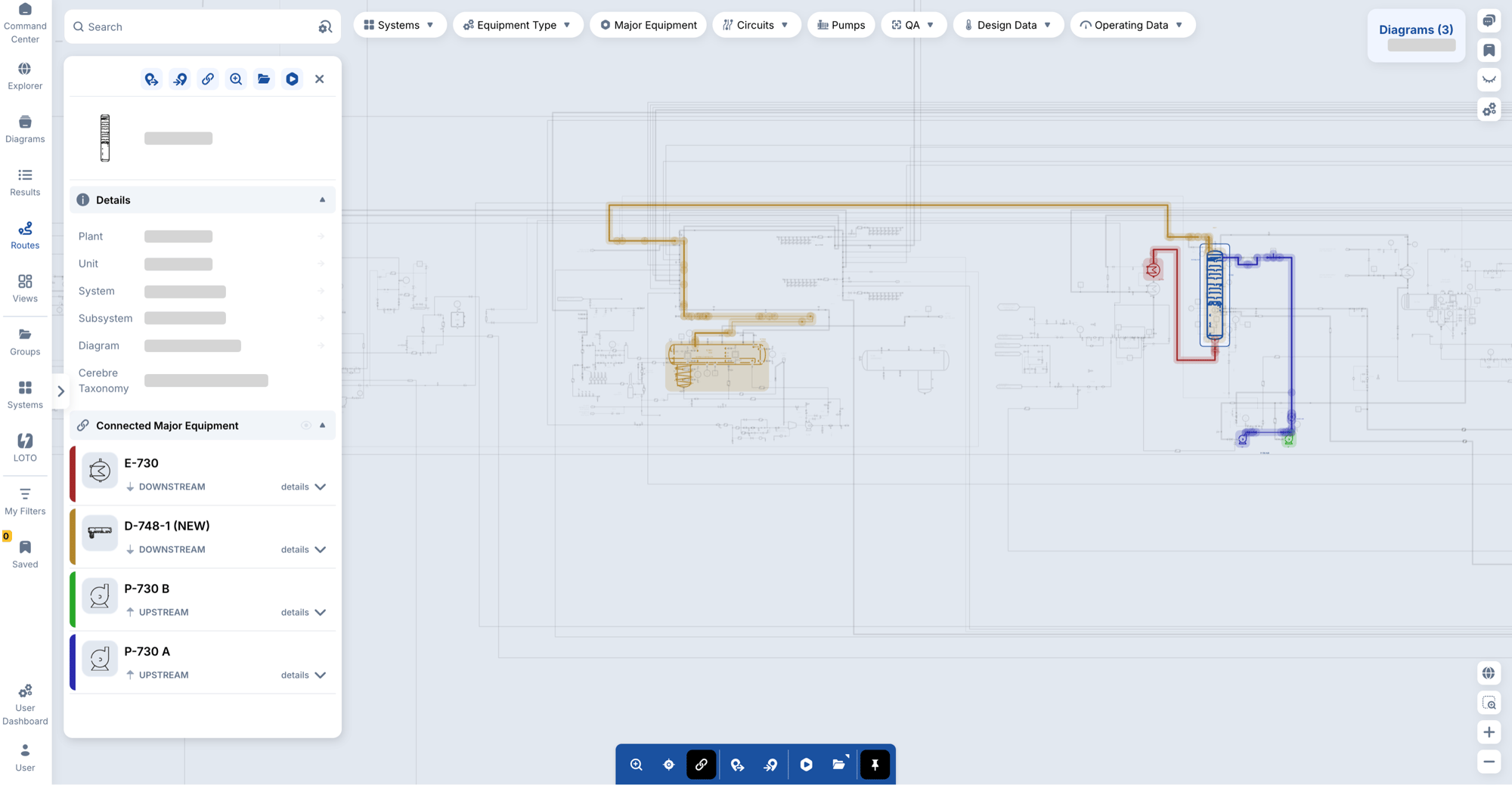

cerebre connects the dots across systems, processes, and people with a semantic, graph-based platform that creates shared understanding and proactive visibility:

- A unified knowledge graph of your plant: assets, operations, documents, events, and sensors, fully contextualized.

- Integration across Maximo, SAP EAM, P-Historian, IoT, DeltaV, Viva, and PLM systems.

- Predictive triggers based on asset health, sensor drift, or weak signals—before they escalate to NCs.

- Asset-centric views for Maintenance, Engineering, and Quality teams to collaborate using the same operational truth.

- Foundation for AI agents to proactively reason over data (e.g., “Is there any open work order on this pump showing signs of failure?”)

Related resources

No context, no intelligence –

The case for a plant data model

Why AI fails without structure and how a data model gives your plant the context it needs.

Digitizing the plant –

The cerebre presentation

See how cerebre helps you transform plant schematics into searchable, smart assets.

We enable your AI –

An overview document

Learn how PlantGraph powers AI with data that’s contextual, connected, and usable.

Example use case for Amgen

Before cerebre

- A critical freeze dryer’s vacuum pump degrades mid-batch

- The issue isn’t caught until there’s a product loss

- Downtime triggers a CAPA investigation, and weeks are lost

After cerebre

- Pump sensor readings start to drift from baseline

- cerebre’s knowledge graph flags no active work order

- System recommends inspection before batch start

- Maintenance is completed proactively, batch saved

Let’s co-design a demo

We’d like to show Amgen how cerebre can:

- Demonstrate a working knowledge graph model of your environment

- Build a realistic reliability use case from your asset and process landscape

Book the next meeting to explore the platform and see how this could look for Amgen